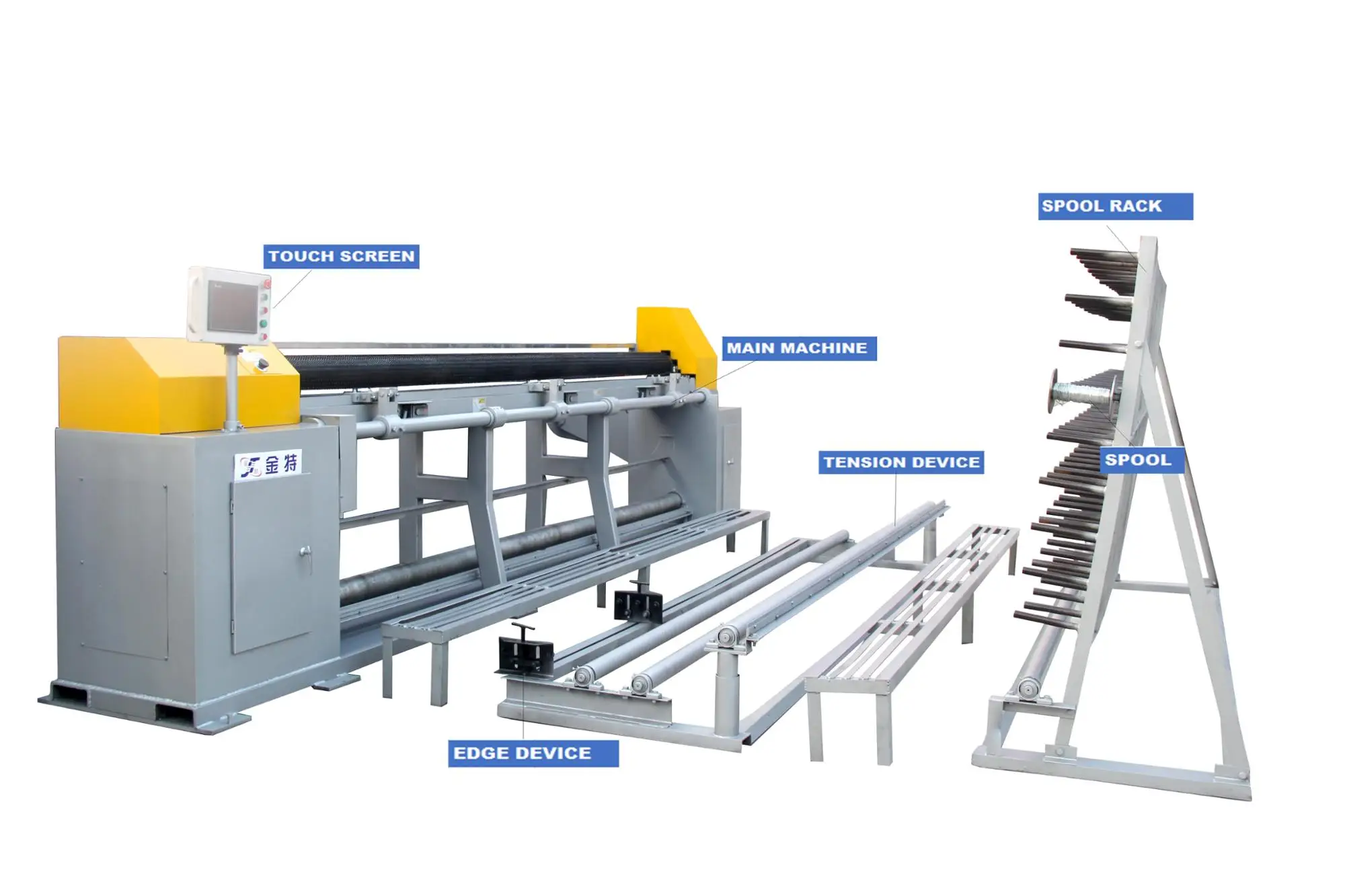

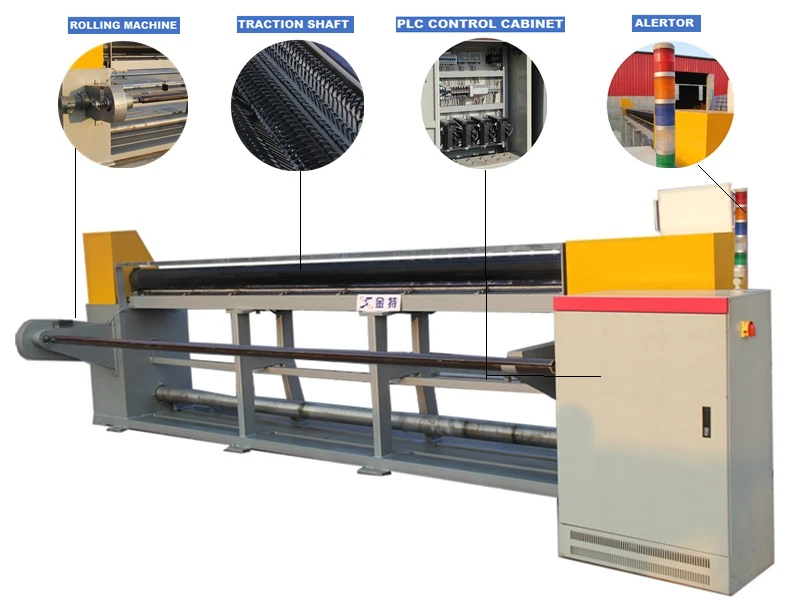

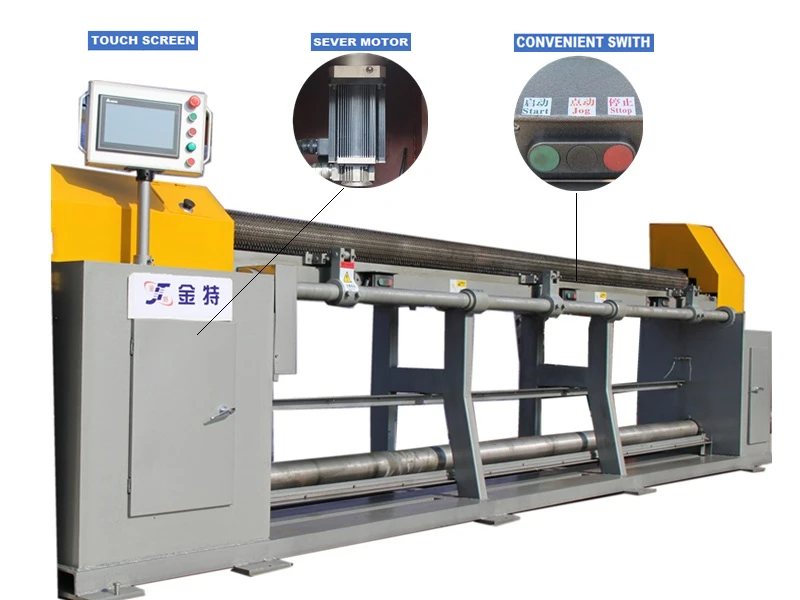

PLC cotrolled with touch screen.More technical parameters can be set and adjusted on the sreen. The machine operated

Advantage:

1. One set of main machine can only produceone mesh size.

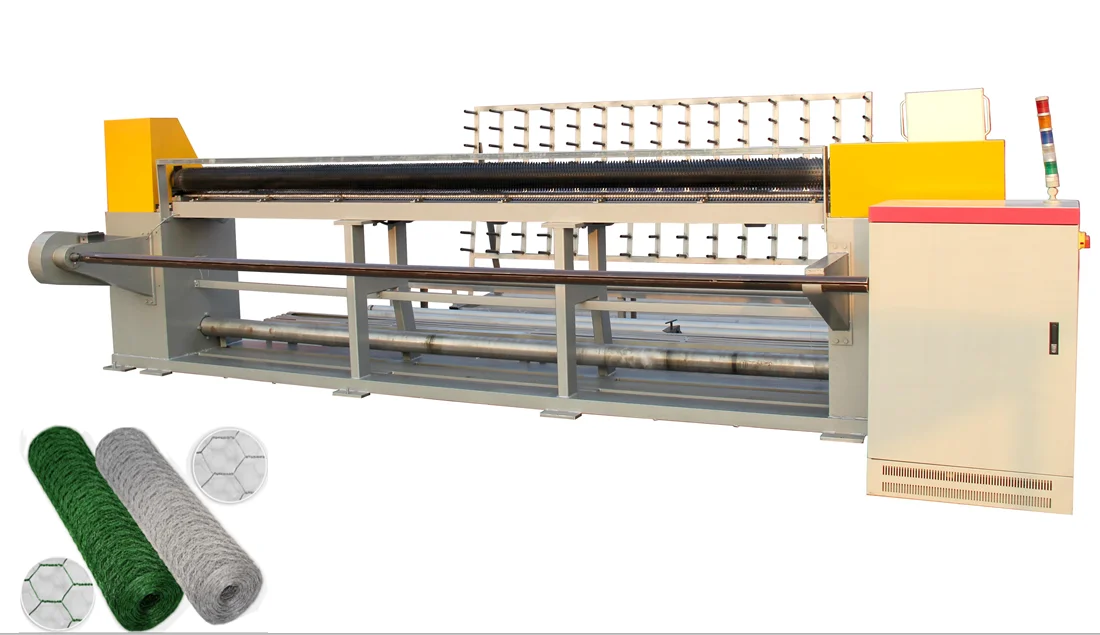

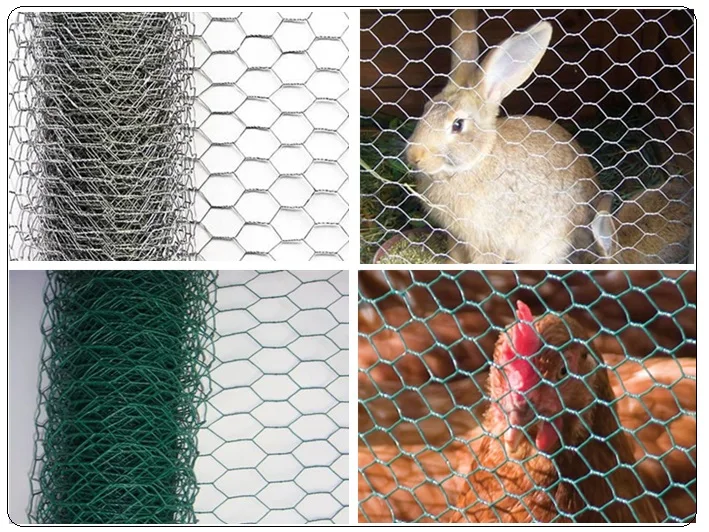

Feeding chicken, rabbit, duck, geese, fish and other poultry or small animals. Style can be fence and cage.

>Contact Us now

| MODEL | MESH WIDTH (MM) | NETTING WIDTH(Meter) | WIRE DIA (MM) | SPEED (Meter) | OUTSIDE DIMENSIONS(Meter) | MOTOR (KW) | WEIGHT (Ton) |

| 1/2" | 15x22 | 1.5-4.7 | 0.35-0.7 | 65 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 3/4" | 20x35 | 1.5-4.7 | 0.35-0.7 | 85 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 1" | 25x38 | 1.5-4.7 | 0.35-1.2 | 100 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 1.2" | 30x40 | 1.5-4.7 | 0.35-1.2 | 110 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 1.5" | 40x53 | 1.5-4.7 | 0.5-2.0 | 150 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 2" | 50x85 | 1.5-4.7 | 0.6-2.2 | 170 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 3" | 80x100 | 1.5-4.7 | 0.6-2.4 | 200 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

| 4“ | 100x140 | 1.5-4.7 | 0.8-3.0 | 220 | 4.2-6.2X1.7X1.6 | 11.6 | 3.8-5.0 |

1. One set of main machine can only produce one mesh size.

2. One set of main machine can make several wire diameters.

3. You can weave two or three net with the same machine.

4. Adopt the principle of clockwise and counterclockwise twisting; no need to make iron wire spring form to increase productivity.

Q: Are you the factory?

A: Yes,We are a professional wire mesh machines manufacturer. We dedicated in this industry for 22 years. We can offer you competitive machines.

Q:Where is your factory located? How can I visit there?

A:Our factory is located in ding zhou county, hebei Province, China, about 3.5 hours by car from Beijing .All our clients, from home or abroad, are warmly welcome to visit our company !

Q: What is the voltage ?

A: To ensure each machine runs well in different country and region, we will choose different voltage like 220V 50HZ; 380V 50HZ; 415V 50HZ;440V 60HZ etc

Q: How much is your machine ?

A: The price is depended on 3 factors:wire diameter, mesh size,and mesh width.

Q: What is your payment terms?

A:Usually by T/T ( 30% in advance, 70% T/T before shipment) or 100% irrevocable L/C at sight, or cash etc. It is negotiationable.

Q: Do your supply includes installation and debugging ?

A: Yes. We will send our best engineer to your factory for installation and debugging. The cost will be quoted separately if you need such service.

Q: How long is your delivery time?

A: If we have in stock, delivery to Tianjin port about 5 days, No stock, it will be 30 days after received your deposit.

Q: How can you guarantee the quality and the warranty?

A. We have an inspection team to check the products at all stages of the manufacturing process-raw material, welding process and test the finished products, etc. 100% inspection in assembly line to achieve the required quality levels.